Multi Function

STARPAK bag can be use for all kind of free flowing goods, such as :

- Cement

- Building Material

- Fertilizer

- Chemical or Resin

- Flour

- Animal Feed

- All Powder and Granular form of product.

Strength

- Our STARPAK bag is very durable, thanks to the sophisticated latest technology machinery and the character of Polypropylene material used to produce the Woven Fabric.

- The shape is robust and versatile; it is resistance to rough handling, dropping, pressing, or rain so the number of lost bag can be minimize.

Water Resistance

- Due to the character of material use (Polypropylene), the bag is not affected by any form of moisture, unlike paper.

- However, this does not mean that the STARPAK bag is always watertight. In some application the bag must be produce with Micro perforations to give the necessary air permeability.

- Micro perforations is the new feature which only can be found in the latest edition of the Conversion Machine.

- The new Micro perforations system is given assurance on having the air permeability at highest standard in the market today.

- This new feature give the ability for the bag to be air tight to highly air-permeable for filling or breathing the goods and yet ensure perfect protection of your valuable pack material at the highest standard

The Space Saver

STARPACK BLOCK BOTTOM design bag gives the bag a brick shape after filled so it can be stack and form a perfectly shape pallets. With the brick square shape it will save the Storage, Transportation, Loading and Unloading space comparing to other type of packaging. STARPAK bag is suitable for all manual and fully automatic production and handling methods.

STARPACK BLOCK BOTTOM design bag gives the bag a brick shape after filled so it can be stack and form a perfectly shape pallets. With the brick square shape it will save the Storage, Transportation, Loading and Unloading space comparing to other type of packaging. STARPAK bag is suitable for all manual and fully automatic production and handling methods.

Efficient Production

- Less breakage and lost during Filling process, Handling, and transportation meaning more productivity.

- This production optimization can be achieved start from Filling, handling, transportation, loading and unloading process.

- Due to the highly sophisticated machinery use for production, all the specification is produce to the optimum perfection.

Eco Friendly

Material used for STARPACK bag is Polypropylene which is categories Non-Toxic material. With the Newest Technology this bag received no glue and it only use patented hot welding process so there is no toxic glue used during production. This is also means it is not harmful for soil and water when in contact during use or when dumped after use. If the breakage and loss can be minimize means less air and water pollution caused by lost filling goods and broken sack.

100% Recyclable

Due to the nature of material used; STARPACK bag is 100% recyclable because it is made from 100% virgin Polypropylene. It can be recycled and to be use for household-grade plastic or high quality plastic molded product for export market.

Save Material

As a result of material characteristics and special production process, The low weight of STARPAK bag can be as low as 75g compared to Plastic Film or 3-layer paper bag with weight average more than 150 gr. An economical use of raw material not only help to minimize cost, it is also valuable contribution to the preservation of our environment.

As a result of material characteristics and special production process, The low weight of STARPAK bag can be as low as 75g compared to Plastic Film or 3-layer paper bag with weight average more than 150 gr. An economical use of raw material not only help to minimize cost, it is also valuable contribution to the preservation of our environment.

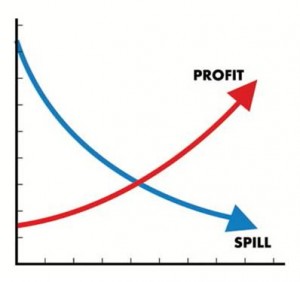

Financial Benefit

- The stability of the product standard specification at the highest level on the production output virtually Optimize production output, minimize the bag breakage, filling failure, replacement of bag/material and cleaning cost.

- Robust and brick shape itself contribute in saving a huge amount of transportation cost and deliver the valuable goods in perfection.

- This all combine together will save huge amount of money by using “STARPAK” bag.

- Pack your valuable goods in our bag meaning your goods will reach your customer in perfect condition so it will give you more trust and market share toward your company.